Support stamping parts production only Hayashi can offer.

“Support stamping parts production”. It’s our history and origin of trust from our customers.With our “net work” as a trading company and specialties only Hayashi have,

we suggest supportive products and services, from press and die components to 3-dimensional special items. We’d like to contribute to development of our stamping industry.

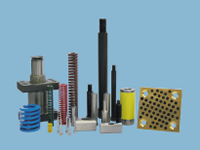

Press Die Standard Components

The motto for Hayashi’s press die standard components is High Quality, Quick Delivery, and Satisfactory Price.With support by many customers, we contribute to Japanese press die making.

Gas Springs

Power for molds. BESTEC gas springs have been used by famous car makers in Japan. You can contact us, sole agent in Japan.

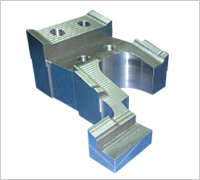

Special Order Parts

From cast profiling to sheet metal working, we can deal with any kinds of process. We can handle 3D data, and satisfy you with prompt quotation and secure delivery.

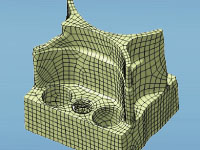

ReKACO Reverse Engineering System

Our ReKACO system is not just reverse engineering, but system to make old parts reborn. Our skilled staffs offer improvement proposal to you with their knowledge and experience about molds.

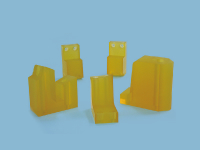

Urethanes and resin parts

From standard parts with quick delivery to special order parts made from supplied drawing, we can respond flexibly.

Shim Plate

Hayashi’s shim offers +/-0.001 (at finest) tolerance for the thickness and wide selection of sizes. Many customers use them and are satisfied.‘’Ki‘ has many meanings in Japanese. ‘’Tree’’, ‘’Hope’’ and ‘’Happiness’’. ..

’Hayashi’’ means ‘’grove’’ in Japanese. A grove is composed of many ‘’Trees’’.

Hayashi would like to support our customers you by being your ‘Ki=Tree’ by spreading branches , rooting largely and deeply.

Hayashi would like to be your ‘Ki=Hope’Hayashi would like to share ‘Ki=Happiness’ with you.

Our new brand ‘’KiKi’’ was named from Hayashi itself and our philosophy.

![]()

Hayashi supply the system including the function as a maker, we’re not just so-called a trading company, but would like to be the part of our customer’s manufacturing. Use this system, then you’d realize how long and how much you had took your time and cost to have quotation, proceed order and manufacture, and would know how efficient your work flow would be and how much you could save your time by outsourcing to us.

Until now and from now on too, having based on prompt quotation reply, quick delivery, and excellent quality, Hayashi keep growing with fresh ideas produced by our wealth of experience, and provide high-valued added service to our customers.

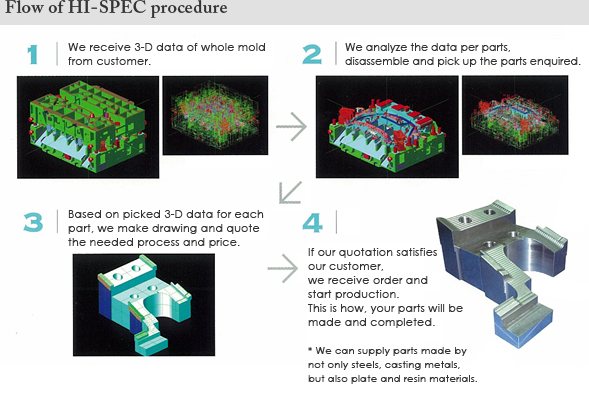

3-D designing have become more and more popular recently to make production facility.

It made us possible to check the structure and study by simulation etc, at the designing stage, which had been difficult by 2-D drawing, this is how manufacturing progressed outstandingly. On the other hand, it’s the undeniable fact that 3-D designing brought us the numerous time (cost) at the each stage of quotation, ordering, manufacturing. Responding immediately to such backdrop, to be as a part of customer’s manufacturing, we set up the system “HI-SPEC”.

Just give us the 3-D data, then time-consuming disassembly to 2-D drawing would be operated by Hayashi. Hayashi make it possible to respond quickly to quotation, parts manufacturing, and batch delivery. Keeping high level for special parts of course, we make customer satisfied by using our wide net work fully and efficiently.